What's So Great About CFRP?

Why Carbon Fiber?

Carbon-fiber reinforced polymers (CFRP) are a relatively new technology whose unique structural properties make them ideal for industrial infrastructure repair.

What Is CFRP?

Carbon fiber was invented more than 150 years ago, but in the last few decades new manufacturing processes have unlocked the qualities that make it such a powerhouse material. So just what is CFRP?

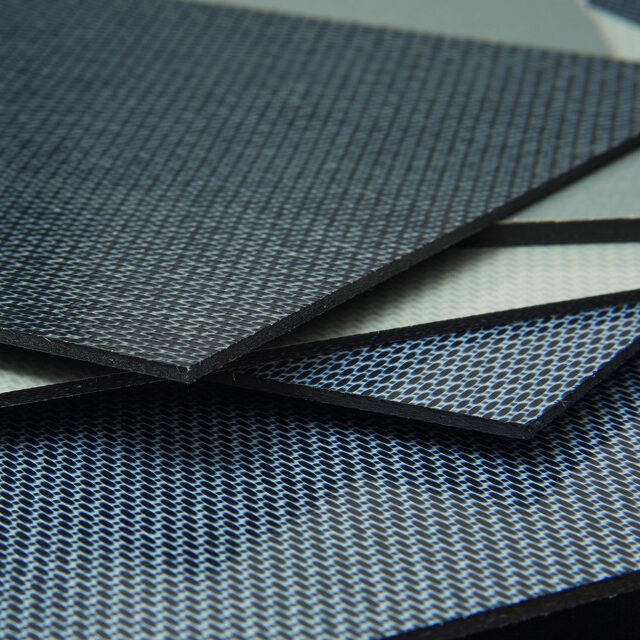

In brief, CFRP consists of carbon fibers woven together and impregnated with resin. What, then, are carbon fibers?

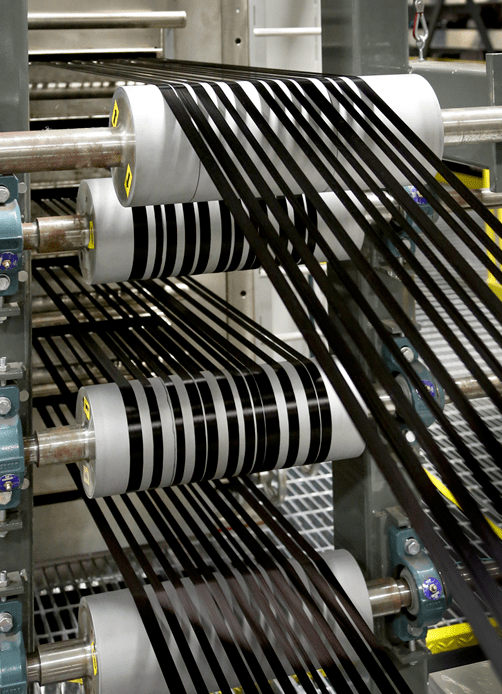

Carbon fibers are microscopically small filaments, much thinner than a human hair, made from extruding petroleum-based materials such as polyacrylonitrile (PAN). Between 1000 and 60000 filaments are combined into a yarn, which is then wound onto a spool.

Then the yarn is subjected to high temperatures, first for oxidization and then carbonization. The resulting threads undergo surface treatment and sizing. Finally, the carbon fiber is wound around a spindle, ready to use.

Properties of CFRP

In a nutshell, carbon fiber-reinforced polymers are strong, durable, and lightweight. These properties have made CFRP ubiquitous in a wide range of applications, from aerospace to sports equipment.

Lightweight

For a material as durable and strong as carbon fiber is, it is remarkably light. On a per-unit basis, CFRP weighs around 80% less than steel and 40% less than aluminum.

Durable

Carbon fiber is highly resistant to corrosion, especially from alkali, and it will never rust. Additionally, CFRP has low thermal expansion, so its properties don’t change much under normal temperature fluctuations. It is especially resistant to high heat conditions.

Strong

This is where CFRP really shines. Sstrength can be measured in several ways, and carbon fiber is superlative in most of them. It has particularly high fatigue strength, high tensile strength (ability to withstand loads that stretch it), and an extremely high strength-to-weight ratio. While steel is superior in compressive strength and rigidity, CFRP’s remarkable strength-to-weight ratio makes it ideal for most applications.

Using Carbon Fiber Composites In Industrial Repair

CFRP’s unique qualities make it a superb material for repairing industrial infrastructure. Next has developed an expertise in the use of carbon fiber composites to fix corroded or compromised concrete and steel infrastructure elements. This includes pipes, tanks, beams, walls, and floors. Over nearly two decades, Next Composites has perfected the art of matching CFRP and other advanced materials to the precise requirements of the infrastructure problem at hand.

We have used carbon fiber and advanced coatings to address failing infrastructure at nuclear and fossil-fuel power plants, hydroelectric facilities, residential high-rises, mining facilities, agricultural processing plants, and more. Nearly any situation that calls for the repair of a concrete or steel element can be addressed more effectively – and cost-effectively – with CFRP.